Introducing our ‘DO: Lean’ series

Our DO: Lean series is made up of bite-sized, one hour sessions, where we introduce you to Lean skills which you can apply in your day to day work.

This series is aimed at all staff – whether you are manager, team member or academic staff member.

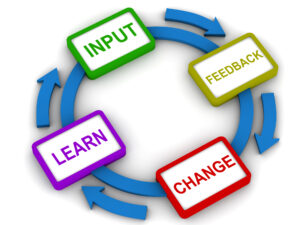

The series will provide a practical introduction to Lean thinking, a starting point for your journey towards developing a continuous improvement mindset where you develop the ability to find ways to improve value and efficiency in how you work. This series replaces our previous one-day Fundamentals of Lean/White Belt course.

The series will provide a practical introduction to Lean thinking, a starting point for your journey towards developing a continuous improvement mindset where you develop the ability to find ways to improve value and efficiency in how you work. This series replaces our previous one-day Fundamentals of Lean/White Belt course.

When new sessions are scheduled they will be made available via the InfoHub Booking Centre.

DO Lean: Think Lean

How do we know if we are focusing our efforts on the right things? How can we deliver a better service without increased effort – or maybe with less effort? How can I develop a culture of continuous improvement in my team? This session provides a practical introduction to Lean thinking designed as a starting point for your journey towards using a continuous improvement mindset – where you naturally seek to improve value and efficiency as part of how you work – while focusing your effort on what matters most.

Session goal: To understand the key Lean principles and able to consider them in the context of daily work.

DO Lean: Defining Success

How can we seek to continuously improve if we are not clear on how we define success? This session shows you how to start with your team’s purpose, understand who your customers are and what your customer values. You can then start to understand the difference between value and waste in our work and what constitutes success.

Session goals:

- Understand what is meant by customer and value

- Be able to identify value in a process

- Hands on experience in assessing the ‘voice of the customer’

DO Lean: Process Mapping

We are all experts in the details of what we do but how do we step back and reflect on what is happening? How can we help others clearly understand what is happening? This session introduces you to process mapping as a way to visualise how things work, making it easier to discuss issues/ opportunities and to see clearly what we might have otherwise missed.

Session goals:

- You will get hands-on experience of process mapping.

- You will become familiar with the various components of a process map and how to put them together.

DO Lean: Analysing a Process

How can we easily identify issues – or opportunities to create efficiencies – in a process? How can we show others where an issue lies so that they understand the need for change? This session takes you through a practical exercise that gives you the tools and the language for identifying and talking about process issues.

Session goals:

- You will be able to spot common process issues by looking at a process map.

- You will be able to identify examples of waste using TIMWOODS.

DO Lean: Getting to the root of a problem

How many times have you made a fix only for the problem to resurface, or another issue to crop up in its place? How often have you struggled to convince someone of what the right thing to fix is? This workshop looks at how we can challenge our assumptions using root cause analysis to address the question of “what is the right thing to fix so the problem goes away for good?”

Session goals:

- You will get hands on experience using some root cause analysis tools: 5 why’s and Fishbone diagram.

- You will understand the context in which each tool is useful.

DO Lean: Brainstorming solutions and gaining consensus

How do you come up with a solution when the solution isn’t obvious? How do you get others on board with a change when they don’t agree with it? This session looks at how you can use creative thinking techniques with a group to identify and reach consensus on a solution to be implemented

Session goals:

- You will be able to understand the complexity of issues and identify those that need further consideration.

- You will be able to apply creative thinking tools such as anti-solutions to work with a group to identify solutions.

- You will be able to prioritise solutions using a PICK chart.

DO Lean: Making change stick

You have put lots of work into making the improvement but how do you make sure the value lasts? How do you make the changes stick? This session looks at the ideas and tools of the ‘Control’ phase of the Lean Six Sigma process, with control meaning – how do you sustain the gains?

Session Goals:

- Understand the importance of ‘control’ for process performance.

- Understanding standard work and standard operating procedures.

- Able to put build and use a simple control plan.