How to put your Lean training to use using an A3 template

By Olga Murdoch, Agile Lead.

What is the A3 used for?

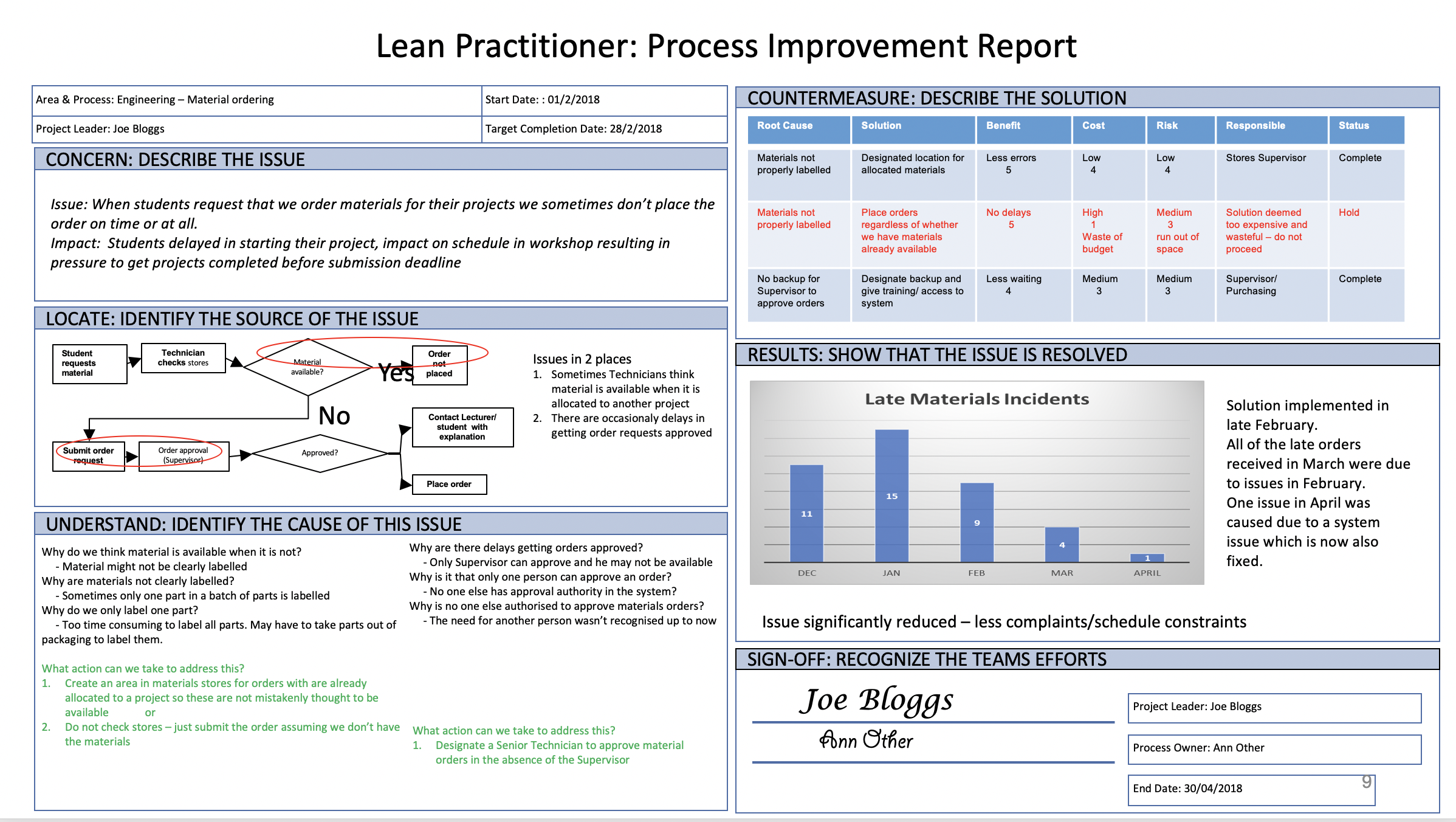

In Lean, the A3 (yes, named after a piece of paper larger than A4) report gives you both a problem solving process and a tool for effectively communicating improvement.

Why should someone use it?

The A3 template is structured in a way that, when you complete it, ensures you are following a Lean problem solving process. The A3 problem solving process is effective and repeatable, making it easier for all of us to solve problems and implement improvements.

The A3 template also enables you to communicate what is important about your project/initiative in a visually impactful and easy to understand way.

You can use the A3 for solving problems of any scale.

Directions on how to use it

Complete the A3 problem solving process and report template step-by-step using the instructions below.

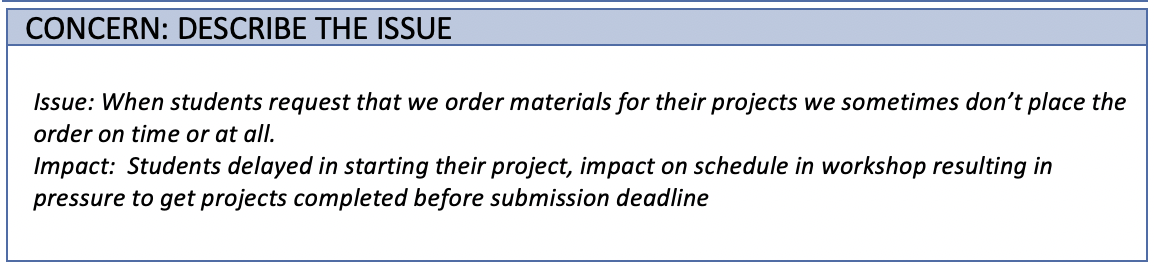

Step 1: Describe the process issue and its impact

It is important to describe the actual issue at the start of your problem solving effort. When we are very close to a problem it is sometimes easier to describe the solution we think we need than the problem we are trying to address.

Example

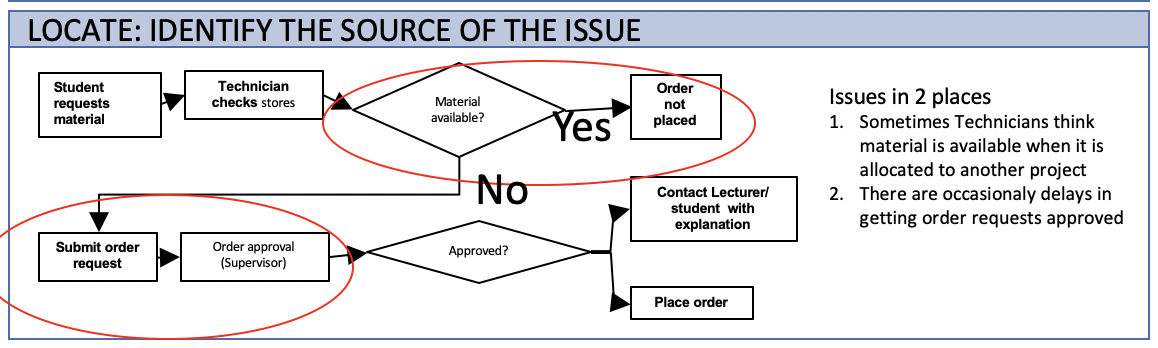

Step 2: Identify the source of the issue

Show, using a simple process map where the issue arises. A process map is a visualisation of how a process flows step by step, including decision points, loops, handovers, etc.The experience of mapping out the process can be quite revealing, even to those of us who are experts in the process at hand, once you get down to the detail. You can see a guide to creating a process map here.

At this point you might consider waste analysis TIMWOODS. You can differentiate by process steps which are waste versus value adding by giving each a different colour.

Once you have mapped out the process highlight the part(s) of the process in which the issue you previous described are arising.

Example

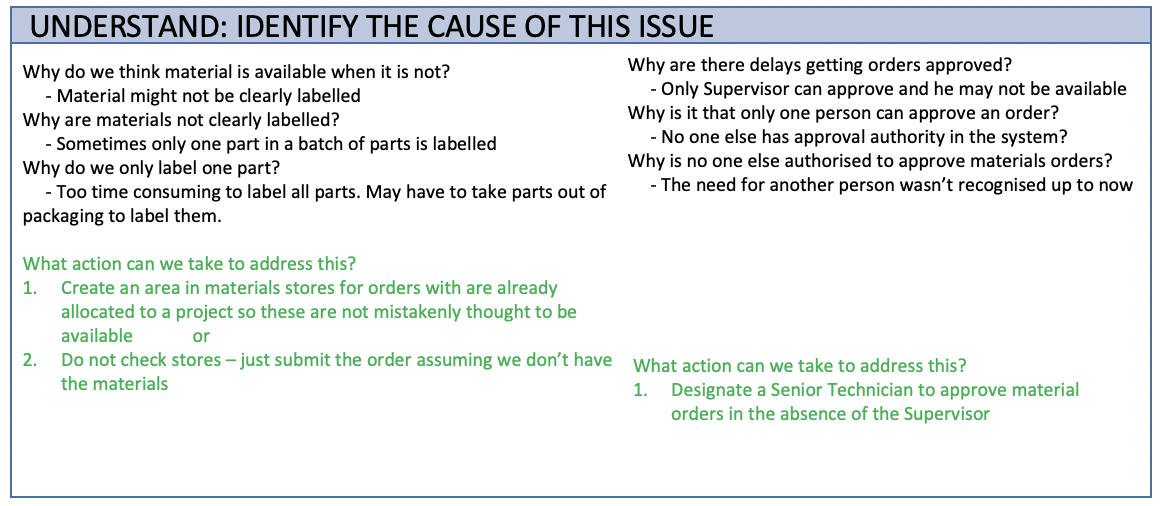

Step 3: Identify the most likely causes of the issue

Now we know what the problem is and where it is happening we have a good foundation for challenging our assumptions and getting to the real root cause of the problem. Use a tool like the 5 Why’s or a Fishbone diagram to brainstorm causes for the issue. Once you have identified the root causes, consider what actions can be taken to address them.

Example using 5 why’s

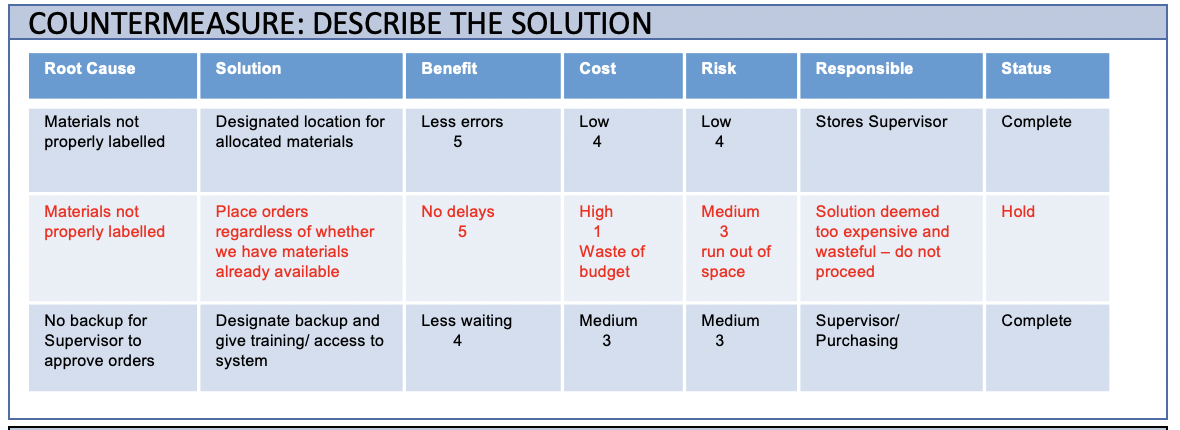

Step 4: Describe the solution

At this point, we have provided evidence of an issue and discovered the root cause(s) we need to fix to effectively solve the problem. Depending on the issue at hand, the solution may be obvious or it may be a little trickier. You might find affinity brainstorming or reverse brainstorming useful techniques for coming up with solutions with your team. Show what solutions have been chosen to be implemented

Example solution screening

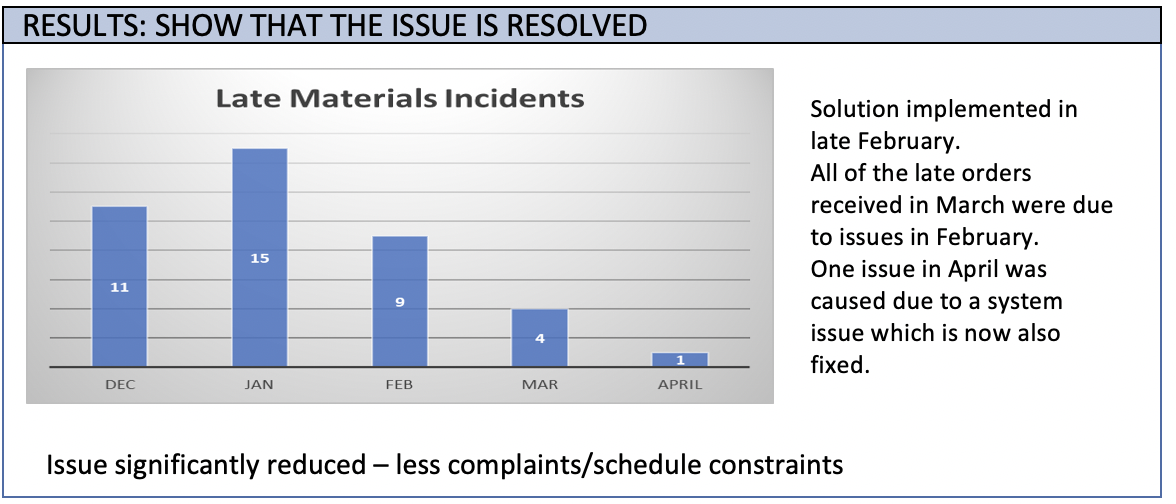

Step 5: Show that the issue is resolved

In Lean problem solving it is important to show the before and after so that we know the impact of our efforts and we can effectively communicate improvements to others. What evidence is there to show that the solution has worked?

Example

What now?

Why not try out this tool yourself, and let me (olga.murdoch@ucd.ie) know how you get on.

Contact agile@ucd.ie for support on using tools such as this and others.